So here is a lesson in not-speaking-too-soon!

Remember this from yesterday:

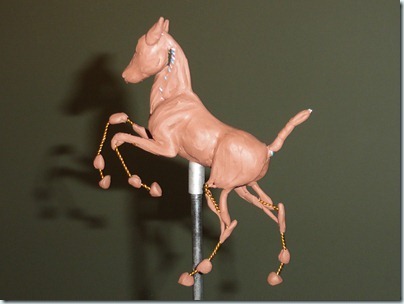

Well I dismantled the mold box and removed the mold without incident and had a lovely tidy mold to be proud of, but when I then made a test “cleaning” cast of white models, unfortunately this happened:

Eep!! Yep, that’s one broken, ruined mold and two unusable casts.

I was heartbroken! That was until just now when I had a long conversation with my materials supplier who gave me some valuable advice on making glossy models.

I’m quite familiar with chemical reactions causing strange results during casting. Each time I think I’ve got this casting malarkey nailed down, there is always one curveball I’ve not anticipated just ready and waiting to restore my humility and respect for this incredibly scientific discipline.

This time it was alcohol*. The gloss agent I used to get that lovely shiny finish (Testors Glosscoat) does NOT play well with silicon rubber as it contains alcohol. What happened here was that, when I removed the masters from the newly made mold I noticed some of the gloss coating had come away. This is not unusual for any model with a coating (varnish, primer, paint etc) to lose some of it to the mold and normally a simple white casting will remove this residue leaving a perfectly clean mold ready to put into production.

*what?!?! How can alcohol possibly be a bad thing??

The alcohol in the gloss coat, however, somehow reacts with the rubber and they “become one”, so when the liquid resin is poured and adheres to the residue (normally to remove it cleanly from the mold), this time the residue “is” the mold, so it effectively adheres to the mold!

You can see that poor Victoria above has lost her ear tip and mane tip, this was due to the force I had to use to remove the casts from the mold, they were THAT strongly adhered to it.

So, I now know how to fix the problem; which glosses I CAN use and where to buy them so that’s a job for tonight on my way home from work, then I can start over with this popular pair and finally offer some casts!

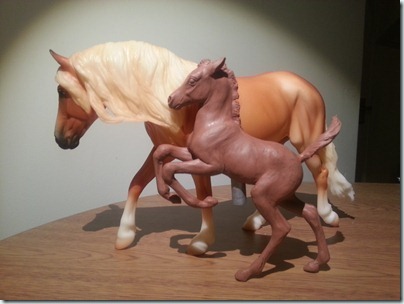

Aaaanyway! Here’s another photo of that other “mystery” model in it’s mold. I’m counting my lucky stars today as I had also treated this model with the same glosscoat but somehow the molds I’ve made have come out perfectly. If this had been ruined it would have been an enormous amount of work to get it back, so although I’ve been stung with Victoria and Albert, Lady Luck was at least smiling on me for this model.

There is always one nice side-effect to experimental casting – hands up if you know what this is: